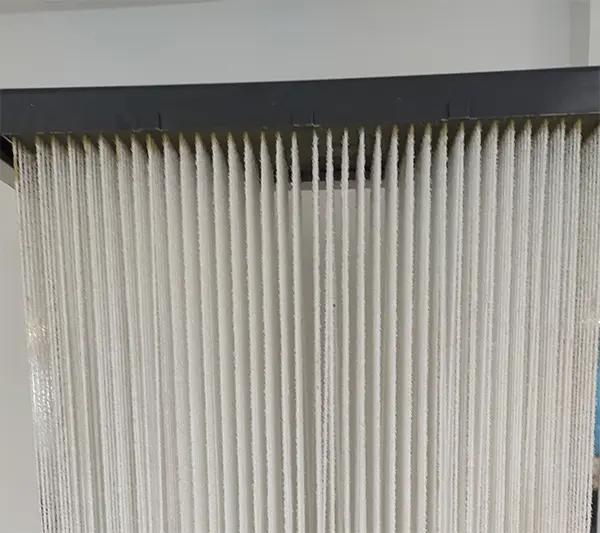

What to do if the membrane pores of the MBR membrane module are blocked?

What to do if the membrane pores of the MBR membrane module are blocked? Blockage of membrane pores is a common problem during the long-term operation of MBR (membrane bioreactor) membrane components. If not handled in a timely manner, it will seriously affect the effluent quality and flux of the system. Here are some methods […]

What to do if the membrane pores of the MBR membrane module are blocked? Read More »